PFC Circuit

What is a BLDC Motor Driver?

A BLDC (Brushless Direct Current) motor driver is an electronic circuit designed to control the operation of brushless DC motors. It controls the motor's speed, torque, and direction by providing precise current and voltage to the motor windings. Lumsyn Electronic specializes in the design and production of top-tier BLDC motor drivers for industrial & home applications

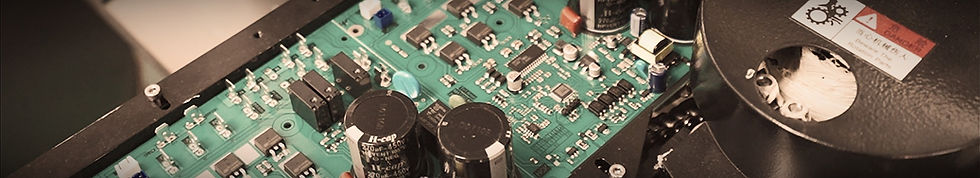

Components of a BLDC Motor Driver

-

Power Stage: Includes power MOSFETs/IGBTs, driving circuits, etc., responsible for converting DC power into three-phase AC power and driving the motor windings.

-

Control Circuit: Includes microcontrollers, sensor interfaces, PWM generators, etc., responsible for generating control signals to achieve precise control of the motor.

-

Feedback Circuit: Includes Hall sensors, current sensors, etc., used to detect the motor's position and current, and feed back to the control circuit for closed-loop control.

Functions of a BLDC Motor Driver

-

PWM Signal Generation: Generates Pulse Width Modulation (PWM) signals to control the on/off time of the motor windings, thereby adjusting the motor's output power.

-

Three-phase Current Control: Precisely controls the current flowing through the three-phase windings of the motor, ensuring smooth motor operation.

-

Speed Control: Adjusts the duty cycle of the PWM signal according to the given speed command to achieve precise control of the motor speed.

-

Torque Control: Adjusts the current of the motor windings according to the given torque command to achieve precise control of the motor torque.

-

Position Control: Achieves precise control of the motor position through feedback signals such as Hall sensors.

-

Overcurrent Protection, Overvoltage Protection, Overtemperature Protection, etc.: Ensures the safe operation of the motor and driver.

Control Methods of BLDC Motor Drivers

-

Open-loop Control: Directly controls the motor based on the given control signal without considering feedback signals.

-

Closed-loop Control: Corrects the control signal based on feedback signals to achieve high-precision control of the motor.

Applications of BLDC Motor Drivers

BLDC motor drivers are widely used in various fields, such as:

-

Industrial Automation: Robots, automated production lines, etc.

-

Power Tools: Electric drills, saws, etc.

-

Electric Vehicles: Electric vehicle drive systems.

-

Industrial & Home Appliances: Evaporative Air Cooler, Fan, Air conditioners, Garbage disposal, Water pump, washing machines, Industrial sewing machine, Vacuum pump, refrigerators, etc.

-

Drones: Drone flight control systems.

Selection of BLDC Motor Drivers

When selecting a BLDC motor driver, the following factors need to be considered:

-

Motor Parameters: Voltage, current, speed, etc.

-

Control Method: Open-loop or closed-loop.

-

Functions: What control functions are required.

-

Environmental Conditions: Operating temperature, humidity, etc.

Future Development of BLDC Motor Drivers

With the continuous development of power electronics technology and microcontrollers, BLDC motor drivers will develop in the following directions:

-

Higher Integration: Integrate more functions into a single chip to reduce costs and improve reliability.

-

Higher Performance: Faster response speed, higher control accuracy.

-

Stronger Intelligence: Support more communication protocols to realize remote control and fault diagnosis.

Summary

BLDC motor drivers are important power electronic devices that play an increasingly important role in modern industry and life. By deeply understanding BLDC motor drivers, we can better select and apply this device, providing efficient and reliable drive solutions for various applications.